Eagle is our new gantry machining centre specifically designed for high speed milling operations on aluminium and engineered materials. The 5 interpolated-axis mobile beam makes this new Breton product the perfect choice for machining complex 3D components used in the aerospace and civil aviation industries.

Efficient and flexible

Even the most demanding jobs are no obstacle for Eagle. Thanks to the flexible configuration of this work centre you can deal with the most demanding milling operations with maximum performance.

Even the most demanding jobs are no obstacle for Eagle. Thanks to the flexible configuration of this work centre you can deal with the most demanding milling operations with maximum performance.

Eagle has a working range which spans from 2500x2000x1000mm up to 20000x5000x2500 mm and over with the double crossbeam and double ram and is ideal for pendular operations.

High speed machining and maximum milling performance

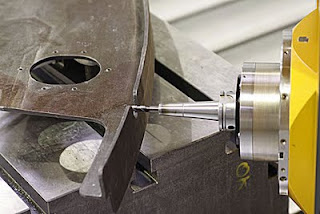

The twist head, which can be positioned at any angle, allows for mounting 40kW spindles with rotation speeds of up to 28000 rpm providing this work centre with improved milling efficiency and performance. This symmetrical twist head with continuous axis C rotation and 0° up to +115° rotation of axis A give Eagle extraordinary and unsurpassed performance ideal when machining complex profiles with 5 axes. The linear axes which travel 85m/min provide this work centre with maximum speed and precision even when milling undercuts.

Safety and improved productivity

This work centre is completely enclosed and all the various assemblies are mounted on the upper part of the machine allowing the operator to work with maximum precision and in total safety.Discover more about Eagle

To learn more about Eagle please contact us at Breton. Write to mail@breton.it or simply fill in the form provided on our Sales Inquiries page or if you prefer call us on +39 0423 769220.

0 comments:

Post a Comment