For multinational corporations or SMEs, the key is always teamwork, strategic vision and persistence.

Like in the case of Merletti Aerospace and Breton's Matrix 1000.

Like in the case of Merletti Aerospace and Breton's Matrix 1000.

(by Paolo Beducci - M&A Meccanica e Automazioni)

Among the classic profiles of Italian family-run businesses we believe some events are more Italian than others, because certain affairs are a more accurate reflection of typical Italian business practice, the will to succeed and the resilience, meaning the ability to adapt to different situations and make positive changes in the organisation when facing challenges.

Incorporated in 1972 by Gianluigi Merletti and his wife Narcisa, Merletti Aerospace was founded under the name of Meccanica Merletti, a general mechanical engineering contractor dedicated to the production of limited series with high value in terms of the exceptional quality of the machining work.

It's worth noting that Merletti operates in a high-tech industrial district: the Varese industrial area, specifically Arsago Seprio, where the majority of Italian aeronautical companies have their headquarters. It should come as no surprise to learn that Varese is known locally as the " the province with wings” (provincia con le ali).

It's worth noting that Merletti operates in a high-tech industrial district: the Varese industrial area, specifically Arsago Seprio, where the majority of Italian aeronautical companies have their headquarters. It should come as no surprise to learn that Varese is known locally as the " the province with wings” (provincia con le ali).

AgustaWestland and AleniaAermacchi, for example, are just two names in a long list of companies whose presence has led to the emergence of a high value added industrial settlement.

From its beginnings, Merletti achieved recognition for its exceptional operational competences and its ability to interact, directly or indirectly, with large industrial concerns, including several companies active in the aeronautical and aerospace industry.

From its beginnings, Merletti achieved recognition for its exceptional operational competences and its ability to interact, directly or indirectly, with large industrial concerns, including several companies active in the aeronautical and aerospace industry.

Arrival of the second generation

In the mid-1990s the Merletti husband and wife team realised they needed to address two types of problems. The first concerned the technological strength of the company, while the second was related to the ability to prepare the family business for a future that would no longer be constrained by the need for the active participation of the two founding partners.

The solution adopted by Gianluigi and Narcisa was to bring their two children (Ruggero and Sabrina) into the business and simultaneously launch an investment plan aimed at modernising the company's capital equipment.

At that time NC machine tools were making their presence felt (also in smaller companies), resulting in a technological paradigm shift of revolutionary proportions.

The solution adopted by Gianluigi and Narcisa was to bring their two children (Ruggero and Sabrina) into the business and simultaneously launch an investment plan aimed at modernising the company's capital equipment.

At that time NC machine tools were making their presence felt (also in smaller companies), resulting in a technological paradigm shift of revolutionary proportions.

The era of highly skilled lathe and milling machine operators was drawing to a close, giving way to the era of machining tolerances of tenths or hundredths of a millimetre and ultimately, microns.

Despite being born and raised in a family focused in high precision mechanical engineering operations, Ruggero and Sabrina had followed different career paths that were far removed from the vocation of their parents. The Merletti husband and wife had now started to plan the introduction of a significant new aspect that was proving extremely successful in terms of the times and results.

Having always focused on Quality in all its operations, Merletti was among the very first small companies to secure EN ISO 9001 certification in 1995, going on to obtain certification in compliance with EN 9100 in 2006.

In the words of Ruggero Merletti – whose role in the family business is to run the Engineering Department and handle technical management – "One of the most significant aspects of our strategy was that at that time many of our customers lacked our qualifications and certifications, either in-house or in their supply chains, so we were perfectly placed to provide the support they needed. In certain cases our company was more highly qualified than the customers we were serving".

Having always focused on Quality in all its operations, Merletti was among the very first small companies to secure EN ISO 9001 certification in 1995, going on to obtain certification in compliance with EN 9100 in 2006.

In the words of Ruggero Merletti – whose role in the family business is to run the Engineering Department and handle technical management – "One of the most significant aspects of our strategy was that at that time many of our customers lacked our qualifications and certifications, either in-house or in their supply chains, so we were perfectly placed to provide the support they needed. In certain cases our company was more highly qualified than the customers we were serving".

Aerospace becomes the core business

The gradual but increasingly massive shift towards the industry that would lead to the company name being changed to Merletti Aerospace, slowly led the Arsago Seprio-based company to focus its operations on increasingly specialised production activities and high-end materials. At this time, the company started working increasingly with special materials such as aluminium alloys, Inconel, high-tensile steels and titanium: all of which, for different and even opposite reasons, call for advanced levels of production expertise.

Apart from the materials, following a trend that was gaining ascendancy also in the aeronautical industry, over the years Merletti Aerospace specialised in high level machining operations and also in the production of mechanical parts with a range of processes from the procurement of raw materials to heat treatments, construction and dimensional checks, galvanic treatments, surface coatings and assembly of mechanical units and sub-assemblies.

The entire process also involves the design and construction of machinery for the production of aircraft parts and equipment, completing the offering with full verticalisation of sub-assemblies, including assembly and testing procedures. The result is a fully-developed industrial system that boasts exceptional levels of know-how and skills.

The entire process also involves the design and construction of machinery for the production of aircraft parts and equipment, completing the offering with full verticalisation of sub-assemblies, including assembly and testing procedures. The result is a fully-developed industrial system that boasts exceptional levels of know-how and skills.

In this panorama, the company clearly needed a design department and machining operations of a level that is greatly superior to the norm. The company's resources comprised a dozen 4- and 5-axis machining centres plus CNC lathes and multitasking machines capable of working with very large size parts for the aerospace industry.

Ruggero Merletti explains, “I believe a company needs to evolve constantly, changing and growing wherever possible.

As soon you relax and start to enjoy the results already achieved, hard-won market positions start to recede. And in a market like ours, which is among the most competitive in existence today, this requirement becomes an absolute must. That's why we decided to make new investments aimed at growing the business, and in our case it was literally a question of growing, having decided to acquire a machining centre capable of working with larger size parts. This decision was aimed at gaining a foothold in a new market area in terms of dimensional characteristics”

As soon you relax and start to enjoy the results already achieved, hard-won market positions start to recede. And in a market like ours, which is among the most competitive in existence today, this requirement becomes an absolute must. That's why we decided to make new investments aimed at growing the business, and in our case it was literally a question of growing, having decided to acquire a machining centre capable of working with larger size parts. This decision was aimed at gaining a foothold in a new market area in terms of dimensional characteristics”

A new push towards the future

Essentially this meant identifying and purchasing a gantry machining centre capable of working on very large parts.

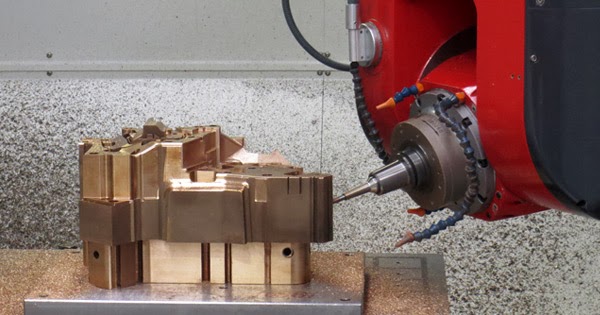

It was no chance that we decided to opt for a Matrix 1000 by Breton, with axis strokes of 3000x6000x1000mm.

In practical terms, this decision allows us to tap into new possibilities, especially in the production of structural components, working with high precision on five continuous interpolated axes in order to perform 3D machining operations: basic requirements that are not easily fulfilled by manufacturers of high-end machine tools.

In practical terms, this decision allows us to tap into new possibilities, especially in the production of structural components, working with high precision on five continuous interpolated axes in order to perform 3D machining operations: basic requirements that are not easily fulfilled by manufacturers of high-end machine tools.

“The best path to follow was to draft a set of specifications – explains Merletti – and then perform a field evaluation of the compatible machines available for purchase. I have to admit that our specifications were highly demanding and difficult for any machine tools manufacturer to meet. After performing an internal selection to narrow the field of potential suppliers, we were left with just four companies, to which we submitted our requests.

And it didn't end there... the specifications also called for field trials and specific guarantees in terms of presence and assistance – both for the choice and installation of the machine and also during routine machining operations. We awarded a score to each machine and each company, together with assessments ranging from the characteristics of the machines to their presence on the market, the number installed machines and numerous additional factors."

And it didn't end there... the specifications also called for field trials and specific guarantees in terms of presence and assistance – both for the choice and installation of the machine and also during routine machining operations. We awarded a score to each machine and each company, together with assessments ranging from the characteristics of the machines to their presence on the market, the number installed machines and numerous additional factors."

The solution is Matrix

"We performed a workpiece test.

The results obtained were all fairly satisfactory, but in relation to certain points Breton was a step ahead of the rest with respect to our requirements. From the vacuum system to the chip removal equipment – critically important when working with high material removal rates per unit time – up to the electrospindle which, in the case of Breton, offers a power rating of 70kW and maximum rotation speed of 28,000 rpm.”

Merletti continues "Over the years Breton has developed a preferential path, with collaboration with one of the top electrospindle manufacturers right from the design stage, thus providing our company with a further guarantee that we would be getting a machine tool that is entirely representative of the state of the art.”

Merletti continues "Over the years Breton has developed a preferential path, with collaboration with one of the top electrospindle manufacturers right from the design stage, thus providing our company with a further guarantee that we would be getting a machine tool that is entirely representative of the state of the art.”

One of the first aspects visible when analysing the Matrix 1000/2TK60 Dynamic is the extremely comprehensive enclosure system, an important requirement when working with materials that are difficult not merely in terms of machining work but also in relation to the management of processing residues. The vacuum system is an integral part of the machine, which is also equipped with a 180-position tool magazine. Given the solution adopted, it's clear that Merletti covered all the bases when selecting their new machining centre!

However, that's what it takes if a company plans to keep one... or even two steps ahead of increasingly fierce competition – competition that is starting to feel the effects of the arrival of newcomers from low-cost countries operating in the lower and less remunerative end of the market.

However, that's what it takes if a company plans to keep one... or even two steps ahead of increasingly fierce competition – competition that is starting to feel the effects of the arrival of newcomers from low-cost countries operating in the lower and less remunerative end of the market.

Ruggero Merletti concludes “While we were impressed by the performance of the machine, we realised we'd chosen well once we started the procedure to install the Matrix. Apart from the fact that rather than a simple machine tool we were dealing with an authentic plant presenting a series of complexities also in the installation stage, I was impressed by the fact that Breton's technicians followed the process step by step, displaying a level of dedication that was invaluable for our company.

The attention we received went well beyond our expectations, including the constant presence of Breton personnel during construction of the foundations, painstaking attention devoted to details, and the maximum availability throughout the process.

The attention we received went well beyond our expectations, including the constant presence of Breton personnel during construction of the foundations, painstaking attention devoted to details, and the maximum availability throughout the process.

And the assistance was provided by a youthful and dynamic team who displayed great dedication and passion for their work, as clearly reflected in every activity and in the way they went about each task.

It seems to me that apart from offering truly exceptional products, Breton understand that it takes a perfectly coordinated team to win the race”.

It seems to me that apart from offering truly exceptional products, Breton understand that it takes a perfectly coordinated team to win the race”.

For INFO and request about 5-axis machining centre Matrix 1000 Dynamic write now to mail@breton.it.

Well, that’s all for today.

Bye-bye

Sergio Prior

Bye-bye

Sergio Prior