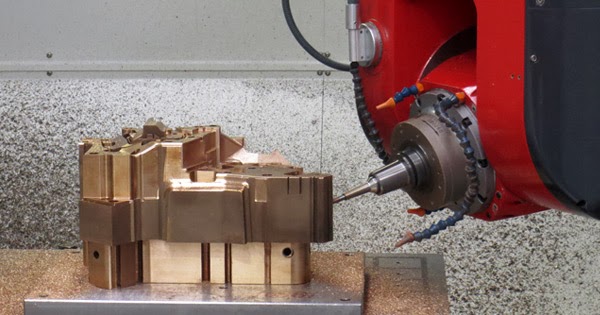

Matrix DYNAMIC is the ideal solution for applications in the aeronautical and automotive sectors, for molding and design.

The unique rigidity and dynamic positioning mean the machine can be used with a variety of components at the highest operating speeds and maximum machining capacity.

The Matrix DYNAMIC in fact, thanks to the high speed of the linear axes up to 60 m/min and Direct Drive head, with a max. rotation speed of 100 rpm and continuous C-axis rotation, offers truly unique machining qualities on complex sections thanks to the 5 continuous axes providing the highest dynamic precision.

The continuous direct drive bi-rotary head, which can be positioned at any angle in its operating field thanks to the powerful hydraulic brakes, lets you use continuous spindle outputs up to 40 kW (51 Nm or 100 Nm) at speeds of up to 28,000 rpm, giving the machine a notablemilling capacity.

The different configurations of the Matrix Dynamix (Z=1000, X = 2,200, Y from 2,500 mm to 4,000 mm,) make the machine perfect for machining medium and large workpieces made of steel, aluminium, resin and composite materials.

The full casing and kinematic mechanisms located at the top of the machine make it extremely safe for the operator to use with the greatest reliability and accuracy during machining.

The full casing and kinematic mechanisms located at the top of the machine make it extremely safe for the operator to use with the greatest reliability and accuracy during machining.

The high quality and accuracy of the machining are also a result of the thermo-symmetry of the structure with a thermal stabilization system for the ball nuts, Z-axis bearings and axis drives, to keep the temperature of these components in line with that of the rest of the machine.

The high quality and accuracy of the machining are also a result of the thermo-symmetry of the structure with a thermal stabilization system for the ball nuts, Z-axis bearings and axis drives, to keep the temperature of these components in line with that of the rest of the machine.