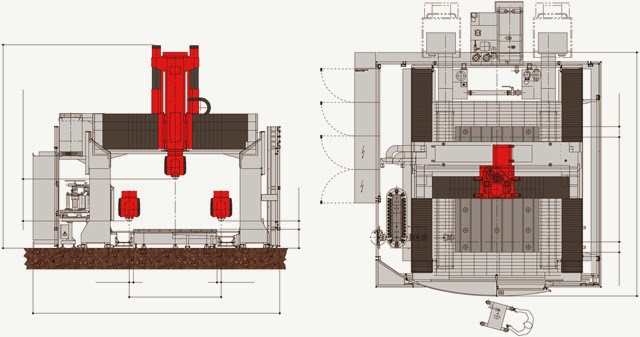

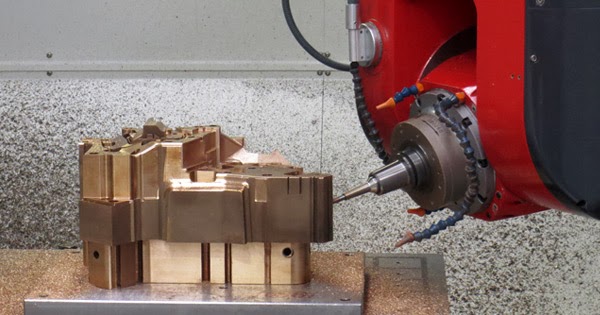

High-speed precision machining centre for milling complex three-dimensional work-pieces which require accurate machining and continuous axis interpolation.

Wide choice of configurations for customized performances

Various solutions for the best machine configuration to satisfy each need:

- Standard model with one working area

- Model with two working areas for pendular machining.

Easy access and perfect visibility

Great accessibility and visibility of the working area thanks to the machine gantry structure with moving bridge and wide frontal doors.

High precision, dynamics and speed with 5 continuous axes

In order to ensure high performances, the new MATRIX 1000 is provided with heavy-duty shoulders manufactured using the ground-breaking Metalquartz technology.

Shoulders consist of a sandwich structure made of stabilized arc welded steel, whose ribbing is embedded in a quartz composite material with a polymeric matrix.

This exclusive technology ensures a very high structural rigidity and vibration damping, which guarantees a better surface finish and a longer service life of the cutting tools.

A superior head

The electrospindles offer always the best machining performance thanks to the cast-iron fork designed head which offers structural rigidity with efficient vibration damping properties. The most high-performance machining centres are provided with Direct Drive motorized heads.

High-speed, Performance and Precision

The carriage and beam travel on properly dimensioned recirculating roller guideways ensure machining precision and stability. Axes are moved by a ground ball screw and double preloaded ball nut assembly.

Maximum axis precision is achieved thanks to the micrometric technology applied. Axes are powered by digital drives and ultimate generation brushless servomotors.

Wide choice of electrospindles

The MATRIX 1000 machining centre can be supplied with a wide range of electrospindles depending on the type of material to be machined. Machining precision is always guaranteed by the thermal stabilising system which consists of a special software designed and developed to compensate natural thermal expansion in the electrospindles when machining conditions vary.

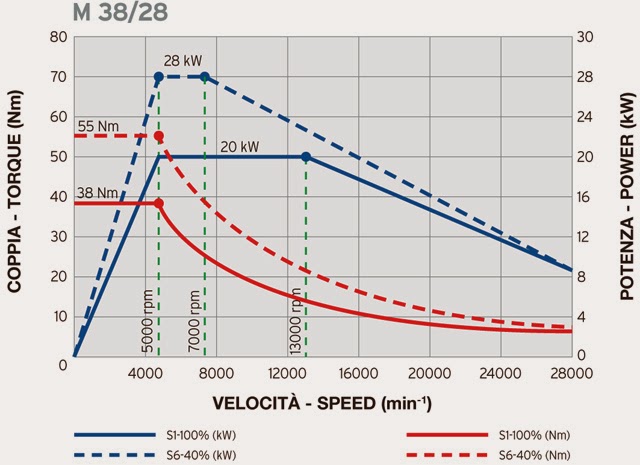

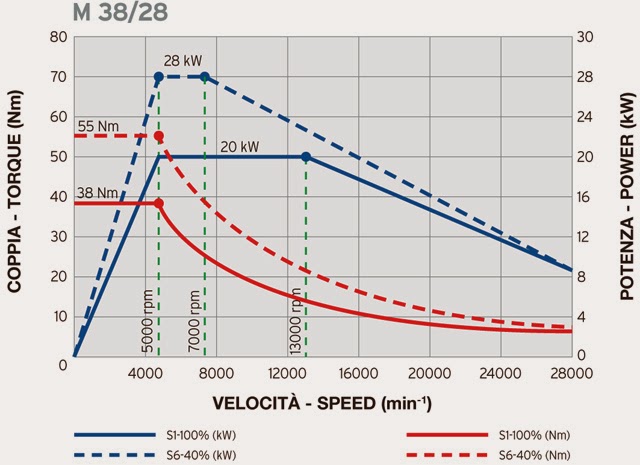

M38/28

A 20 kW electrospindle with a 38 nm continuous torque in S1 and 28,000 rpm is the ideal choice for high-speed machining requirements for steel and light alloy from rough milling to precision surface finishing operations.

M51/28

Electrospindle featuring a power of 40 kW, continuous torque of 51 Nm in S1 duty and 28.000 rpm: the ideal choice for customers requiring high-speed machining on either steel or light alloys, from rough-machining up to precision finishing.

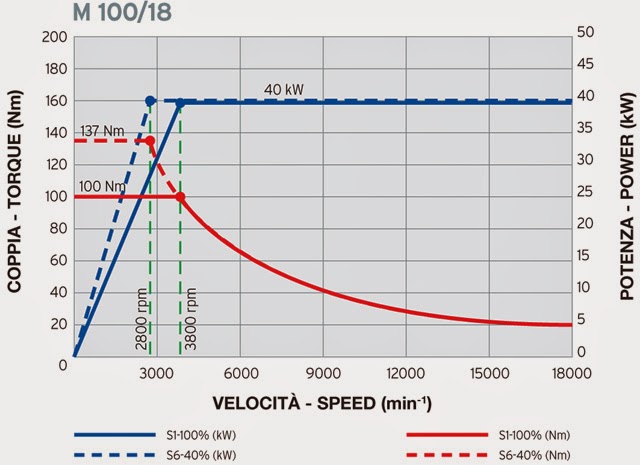

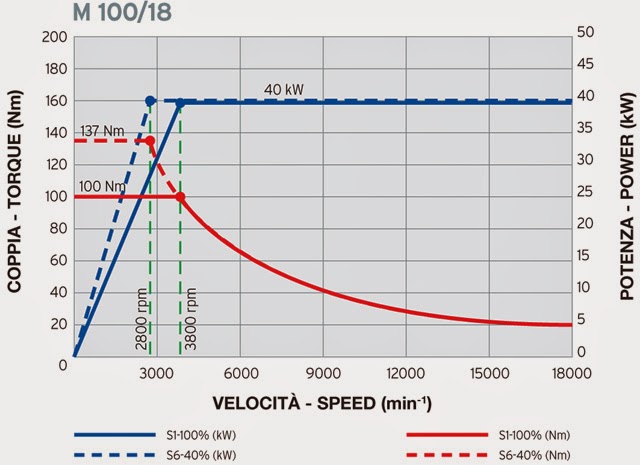

M100/18

Electrospindle featuring a power of 40 kW, continuous torque of 100 Nm in S1 duty and 18.000 rpm: smartly performing any machining operation on either steel or light alloys, from rough-machining up to precision finishing.

Simple and reliable tool magazines

According to the various models, wheel-type or chain-type tool magazines with fast manipulator to reduce tool changeover times are available. Installed outside the work area and therefore free of dirt, these tool magazines ensure the greatest reliability over the time.

Various solutions for the best machine configuration to satisfy each need:

- Standard model with one working area

- Model with two working areas for pendular machining.

Easy access and perfect visibility

Great accessibility and visibility of the working area thanks to the machine gantry structure with moving bridge and wide frontal doors.

High precision, dynamics and speed with 5 continuous axes

In order to ensure high performances, the new MATRIX 1000 is provided with heavy-duty shoulders manufactured using the ground-breaking Metalquartz technology.

Shoulders consist of a sandwich structure made of stabilized arc welded steel, whose ribbing is embedded in a quartz composite material with a polymeric matrix.

This exclusive technology ensures a very high structural rigidity and vibration damping, which guarantees a better surface finish and a longer service life of the cutting tools.

A superior head

The electrospindles offer always the best machining performance thanks to the cast-iron fork designed head which offers structural rigidity with efficient vibration damping properties. The most high-performance machining centres are provided with Direct Drive motorized heads.

High-speed, Performance and Precision

The carriage and beam travel on properly dimensioned recirculating roller guideways ensure machining precision and stability. Axes are moved by a ground ball screw and double preloaded ball nut assembly.

Maximum axis precision is achieved thanks to the micrometric technology applied. Axes are powered by digital drives and ultimate generation brushless servomotors.

Wide choice of electrospindles

The MATRIX 1000 machining centre can be supplied with a wide range of electrospindles depending on the type of material to be machined. Machining precision is always guaranteed by the thermal stabilising system which consists of a special software designed and developed to compensate natural thermal expansion in the electrospindles when machining conditions vary.

M38/28

A 20 kW electrospindle with a 38 nm continuous torque in S1 and 28,000 rpm is the ideal choice for high-speed machining requirements for steel and light alloy from rough milling to precision surface finishing operations.

M51/28

Electrospindle featuring a power of 40 kW, continuous torque of 51 Nm in S1 duty and 28.000 rpm: the ideal choice for customers requiring high-speed machining on either steel or light alloys, from rough-machining up to precision finishing.

M100/18

Electrospindle featuring a power of 40 kW, continuous torque of 100 Nm in S1 duty and 18.000 rpm: smartly performing any machining operation on either steel or light alloys, from rough-machining up to precision finishing.

Simple and reliable tool magazines

According to the various models, wheel-type or chain-type tool magazines with fast manipulator to reduce tool changeover times are available. Installed outside the work area and therefore free of dirt, these tool magazines ensure the greatest reliability over the time.

They can be equipped with an automatic chip coding system containing tool data and information.

Dust extraction and ceiling enclosure

Dust extraction and ceiling enclosure

When machining composite materials and resin, MATRIX 1000 can be fitted with an efficient and effective dust extraction system which is installed on the spindle nose. In addition, top-roof bellows can be fitted to the machining centre creating a complete enclosure isolating the machine from the surrounding areas.

Different models of dust extraction systems are available to satisfy any customer’s requirements.

The ideal cooling system

Depending on the type of machining, the tool cooling system can use a coolant liquid which flows inside and outside the spindle (60 L/min) with fixed or variable (up to 70 bar) internal pressure, or incorporate a spray mist system, or simply use compressed air.

Monitoring and in-process inspections

Depending on the type of machining, the tool cooling system can use a coolant liquid which flows inside and outside the spindle (60 L/min) with fixed or variable (up to 70 bar) internal pressure, or incorporate a spray mist system, or simply use compressed air.

Monitoring and in-process inspections

MATRIX 1000 can be supplied with a laser tool presetter and a radio frequency probe for acquiring work-piece size and coordinates.

So, why don’t you request a quotation for a MATRIX 1000?

Write to mail@breton.it

By-by

Sergio Prior

.jpg)