To serve new markets with its aluminium models for foundry applications, Italmodel has turned to 5-axis machining, choosing the technology and support of Breton, in the form of the recent Matrix 800 2T K25.

Everyone knows Italy as a land of art and artists, but what people often overlook is that the concept of “art” can also be applied to neighbouring fields.

Indeed, in the mechanical arena, when you visit a model shop, you can see with your own eyes how technology combines with human ingenuity to create products that reach almost artistic heights.

Italmodel is very much on that level and has been ever since it was founded by Antonio Guarneri. This family firm, where craftsmanship and industrial production combine harmoniously, is now run by the second generation.

From wood to metal

“Our father set up Italmodel in 1979,” explains Davide Guarneri, who runs the business with his brother Fabio and sister Floriana, “to produce wooden models for foundry applications. Until not long ago, the models required highly specialist, experienced labour. Over the years, technology has made great strides, so much so that in 2001 we bought a 5-axis wood-milling machine. Meanwhile, the business began to diversify: wood is a suitable material for making small batches in the foundry; it is economical but not very durable. For higher volumes, you need metal – like aluminium, although that demands the right tools and a completely different approach in order to be machined profitably.

Today, with the now-common 5-axis machining centres, all it takes to obtain good results is a skilled worker and the right software in your technical office. The key is in refining your processes, understanding how to get the most from the tools, and relying on the machine manufacturer’s expertise, to gain the “tricks and tips” that are vital for maintaining profit margins.”

At this point, we need to take a step back. 5-axis machining – however you do it (positioning, continuous operation, etc.) – is clearly more complex than using a 3-axis machine.

“From this perspective, despite its limitations, the first machine for wood really opened our eyes: it enabled us to gain confidence with a new way of working,” says Davide Guarneri.

“And to be frank, with wood, it is fairly easy to patch up a mistake or blemish with filler. Metal imposes other technological constraints and brings potential risks, not least that a 5-axis metalworking machine is not cheap to buy or run. That is why we evaluated our options very carefully, and we chose a Matrix 800 2T K25 machining centre by Breton.”

Increasingly demanding markets

“Until a few years ago, we could count on a very local clientele, even from Lombardy or neighbouring regions; now, however, we are facing international competition, whose strength is its low labour costs,” adds Fabio Guarneri. “To compete, then, it is crucial to reduce our overall costs without compromising on quality. The only way is to use tools that enable us to cut those costs while maintaining our distinctive high standards.”

5-axis technology has become indispensable for Italmodel.

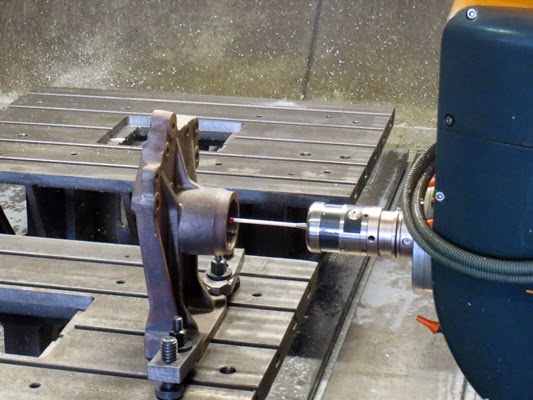

“To complete certain jobs, it is essential to have a 5-axis machine like Matrix; without one, you are forced to turn down some complex projects. Obviously, saying ‘no’ to a potential client is not an option. So being able to rely on a powerful, flexible, high-performance machine is not just a means of boosting manufacturing profitability – it is the only way to stay in business.”

“Of course, just putting a machine in your workshop is not enough: to get the most from it, you need the right software. We have loaded the Matrix model into our CAD/CAM system and used it for simulations: moving from 3 axes to 5 dramatically increases the number of parameters in play. We use the machine in various ways: for positioning, with the 4th axis moving, and for continuous 5-axis machining.

Depending on the workpiece, the production requirements or the desired final quality, it is important to choose the most suitable mode. Even with complex surfaces, often all we need do to finish the job is wipe the workpiece clean with a cloth – as long as you selected the right working mode, as I mentioned.”

Reliability and performance

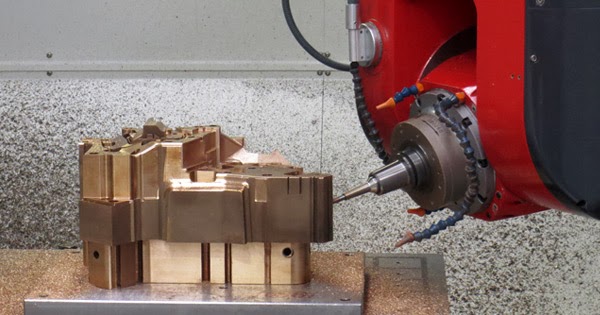

Matrix 800 2T K25 is an interpolated 5-axis vertical continuous machining centre for working different types of material, from steel to aluminium and composites to resins.

For a work area of 2,000x1,600x800 mm (X/Y/Z), it offers a compact footprint and high-level dynamic performance, with maximum axis feed rates of 40 m/min and acceleration of up to 3 m/s2.

The typical Breton dual-drive gantry structure provides a large work area allowing the operator full freedom of movement, in strict compliance with safety standards. Matrix 800 makes it possible to position and machine even large workpieces with ease, combining excellent reliability and safety features with optimum performance. Operators appreciate the Matrix 800 even more for its rigidity, courtesy of the electro-arc-welded heat-treated structure made entirely of steel with suitable stiffening ribs and other reinforcement.

Continuing Breton’s technology traditions, the twist head with continuous rotation of axis C and axis A ideal for machining undercuts with a ±105° rotation enables even complex workpieces to be machined at high speed.

Italmodel uses its Matrix primarily to work aluminium and resin components, but that belies its full capabilities.

“We have made various steel components for other industries, and we have been pleased to note that the machining quality is just the same, even for more stubborn materials, as the extra power kicks in,” confirms Davide Guarneri. “Precision working and finishing is assured, not only by the tight construction tolerances but also by the thermal stabilisation and by the software that compensates for thermal expansion in the electrospindle and for dynamic errors arising as operating conditions vary. The liquid tool coolant and the air for cleaning the tool taper flow within the electrospindle.”

The extra dimension: service

When a company like Breton sells a machine, its responsibilities do not end there. “It has been a considerable investment for us. Initially, we feared that we had bitten off more than we could chew,” confides Davide Guarneri. “But we soon realised that Breton’s service, both pre and post sale, would give us timely, expert answers to all our queries. For example, I had never seen remote support in action before. A while ago, the coolant pumps would not work: the Breton technicians connected to the machine and noted that the problem was caused by a microswitch on the door failing to make proper contact, thus preventing the machine from operating.

We found an accumulation of dirt at a particular point; after cleaning, the machine restarted immediately. The total downtime was less than 2 hours! When you have a delivery deadline approaching, these are the details that make the difference between finishing on time and being late.”

“When we signed the contract, we had the chance to visit the Castello di Godego works in Treviso,” remarks Davide Guarneri. “Seeing how they build and assemble the machines was reassuring, because it showed us just how much dedication goes into making the product that will then be installed in a customer’s workshop – the same dedication that we put into using it.”

Many thanks to Andrea Pagani and TM – Tecnologie Meccaniche – for the material provided.

Have a nice day

Bye-bye

Sergio Prior