Pure flexibility

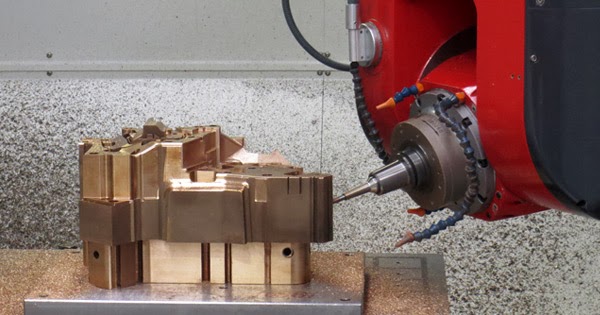

High-speed precision machining centre for milling complex three-dimensional work-pieces that require accurate machining and continuous axis interpolation. Matrix 800 is the ideal solution to satisfy production requirements in the aerospace and automotive, toolmaking and design industries.

Easy access and perfect visibility

Matrix 800 allows optimal accessibility and visibility of the working area thanks to its large front doors and gantry structure.

Precision and Flexibility when machining at high speed with 5 continuous axes

As a guarantee of high performance Matrix 800 is equipped with heavy-duty shoulders built with innovative Metalquartz technology: an high tech material including special resin and a high percentage of quartz to guarantee optimal vibrations dampening and the same thermal expansion as the metal structure it self for enhanced surface finishes and longer working life of the cutting tools.

A Superior Head

All electrospindles offer the highest performance thanks to the cast-iron fork head, which gives both structural rigidity and the ability to absorb machine vibrations.

High-speed, Performance and Accuracy

Carriage and beam travel on generously sized recirculating roller guideways to ensure precision and stability. Axes are moved by a ground recirculating ball screw systems. Optical linear encoders ensure maximum axis positioning precision. All axes are powered by the latest generation brushless servomotors controlled by digital drives.

Electrospindles and Tool magazine

Matrix 800 machining centre can be supplied with a choice of electrospindles depending on the type of material machined.Precision is always guaranteed by the spindle thermal stabilisation system and software compensation of the natural thermal expansion that could be caused by changing operating conditions.

Matrix 800 is available with wheel-type tool magazine with min. 30 tools (150 tools max) installed outside the working area to protect it from dirt and ensure the maximum reliability through time.Tool magazine can be equipped with an automatic tool coding system with chip.

M 48/28

An electrospindle with 20 kW power rating, continuous torque in S1 of 48 Nm and 28,000 rpm is the most appropriate choice for companies that need to perform high speed machining of steel and aluminium, from semi-finishing to precision finishing.

M 64/28

An electrospindle with 37 kW power rating, continuous torque in S1 of 64 Nm and 28,000 rpm is the most appropriate choice for companies that need to perform high speed machining of steel and aluminium, from roughing to precision finishing.

Roof-top bellows and Dust extraction

Ideal for machining aluminium and composites, Matrix 800 can be equipped with an efficient extraction system for composite materials dust installed on the spindle nose, and roof-top bellows that completely seal the working cell, isolating the machining zone from the outside environment.Various alternative fumes and dust extraction systems are available in accordance with specific customer requirements.

The ideal cooling system

Depending on the type of machining, the tool cooling system can use coolant outside or through the spindle (mac 60l/min) with fixed or variable internal pressure up to 70 bar, incorporate a spray mist system or simply use compressed air.

Monitoring and in-process inspections

Matrix 800 can be equipped with a laser tool presetter and a radio frequency probe to acquire work-piece dimensions and coordinates, so to simplify the worpiece setting.

For INFO and request write now to mail@breton.it.

Well, that’s all for today.

Bye-bye

Sergio Prior